Product Overview

The Vertical Shaft Hammer Mill Crusher is a high-efficiency fine crushing machine designed for processing various metallic and non-metallic solid wastes and recyclable materials. Featuring a vertical shaft structure, the machine uses high-speed rotating hammers or rotors to crush, shear, and grind materials into smaller particles. Its compact design, small footprint, and easy maintenance make it ideal for small recycling facilities and laboratories.

Application Scope

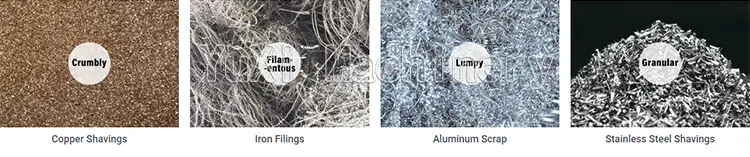

- Waste metals such as aluminum parts, tinplates, cans, and motor shells;

- Shells of waste electrical and electronic appliances;

- Aluminum rims, light scrap steel, and metal offcuts;

- Non-metallic materials like plastics and rubber;

- Small recycling stations, research institutions, and testing sites for sample crushing.

Working Principle

- Raw materials are fed into the crushing chamber via a conveyor. The high-speed rotating rotor drives the hammers to impact, shear, and grind the materials.

- The crushed materials are discharged through a screen mesh—particles meeting size requirements exit automatically, while oversized pieces remain in the chamber for further crushing.

- Optional configurations include dust removal and magnetic separation systems for clean, automated operation.

Advantages and Features

- Compact structure and small footprint – easy to install and move;

- High crushing efficiency – optimized rotor design and hammer arrangement;

- Adjustable output size – changeable screen mesh or hammer gap adjustment;

- Easy maintenance – simple replacement of wear parts, stable operation;

- Low energy consumption and noise – energy-saving and environmentally friendly;

- Strong adaptability – suitable for various metallic and non-metallic materials.