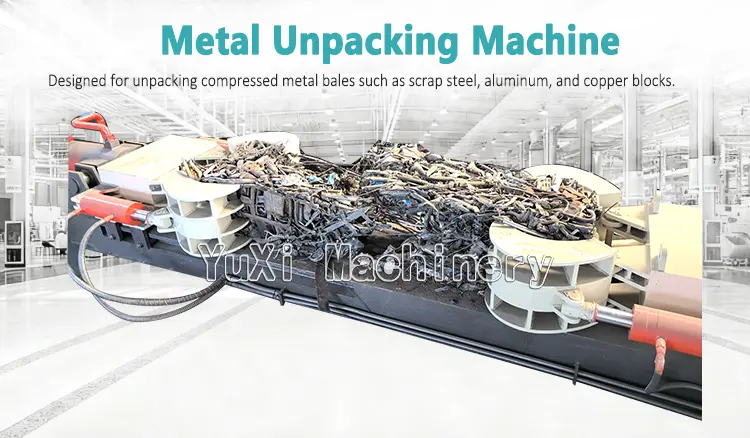

Product Overview

The Metal Unpacking Machine is specially designed for unpacking compressed metal bales such as scrap steel, aluminum, and copper blocks. Powered by a hydraulic system, it efficiently breaks and loosens dense metal packages, preparing them for further crushing, sorting, or smelting. With high automation and strong structure, it is an essential pre-treatment equipment in metal recycling and regeneration plants.

Application Scope

The machine is suitable for:

- Scrap steel, aluminum, and copper bales;

- Compressed blocks from scrapped vehicles, household appliances, and mixed metals;

- All kinds of ferrous and non-ferrous metal packages formed by hydraulic balers.

- It is widely used in metal recycling plants, shredding lines, resource recovery centers, and steel mills.

Working Principle

- Feeding: Metal bales are fed into the unpacking machine by a grab or conveyor.

- Clamping and Positioning: The hydraulic system activates clamps to fix the metal bale firmly.

- Cutting and Decompression: Hydraulic knives or pushers apply force to cut and decompose the dense bale, gradually loosening the material.

- Discharging: The loosened metal pieces are discharged through the outlet to the next stage such as a crusher or separator.

- The process is fully automated and can be integrated with shredding or conveying systems for continuous production.

Advantages & Features

- High Efficiency: Strong hydraulic power ensures fast and complete unpacking of dense bales.

- Robust Structure: Heavy-duty steel frame resists wear and impact, suitable for continuous heavy operations.

- Automation: PLC control system enables automatic feeding, unpacking, and discharging.

- Safety & Environmental Protection: Enclosed operation reduces dust and noise.

- Easy Maintenance: Modular design of key parts for convenient replacement and service.

- Customizable: Adjustable cutting tools and pushing systems to fit different bale sizes and densities.