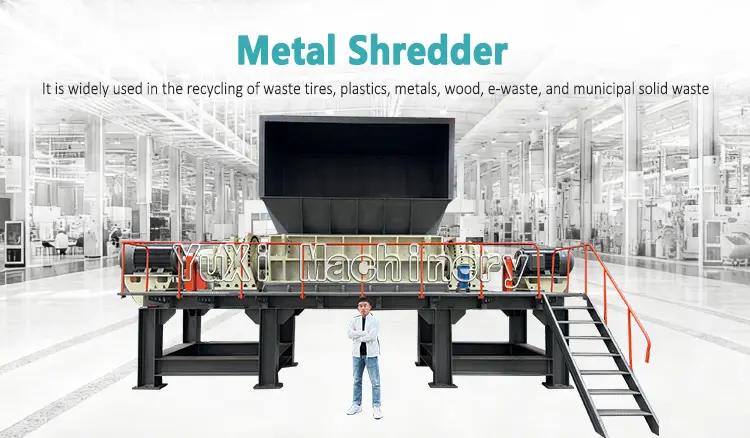

Product Overview

The scrap metal shredder is an environmental recycling machine designed for coarse crushing of various solid wastes. It works through shearing, tearing, and squeezing actions to reduce bulky materials into smaller pieces, making them easier for transportation, sorting, or further recycling. It is widely used in the recycling of waste tires, plastics, metals, wood, e-waste, and municipal solid waste.

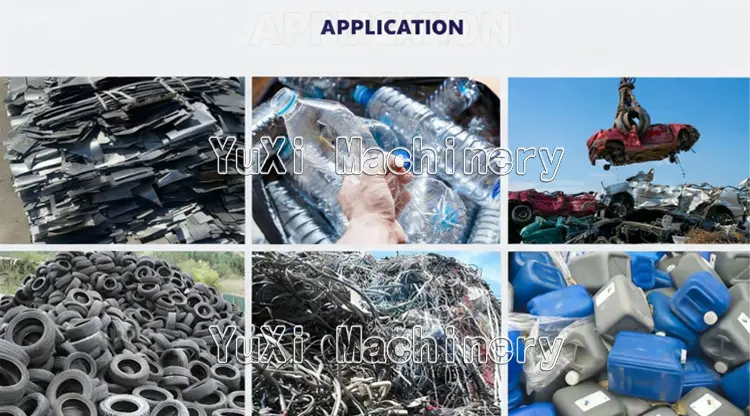

Application Scope

- Waste tires and rubber products

- Various plastic materials (PE, PP, PET, PVC, etc.)

- Scrap metals (such as aluminum, iron, copper, etc.)

- Electronic waste, cables, and circuit boards

- Wood, pallets, and furniture waste

- Household garbage, industrial waste, medical waste, etc.

Working Principle

Materials are fed into the shredder via a conveyor and are cut and torn by rotating blades mounted on the shaft. The motor, driven by a gearbox, provides high torque at low speed to efficiently shred hard and bulky materials. The shredded output passes through a screen mesh; particles meeting the required size are discharged, while oversized pieces remain in the chamber for further shredding.

Advantages & Features

- High torque & low speed: Powerful shredding for a wide range of materials.

- Modular blade design: Easy replacement, long service life, and simple maintenance.

- PLC automatic control: Intelligent operation with overload and reverse protection.

- Energy efficient: Low noise, low dust, and high power efficiency.

- Stable & durable structure: Made of high-strength alloy steel and precision welding.

- Flexible configuration: Available in single-shaft, double-shaft, or four-shaft models according to material and capacity requirements.