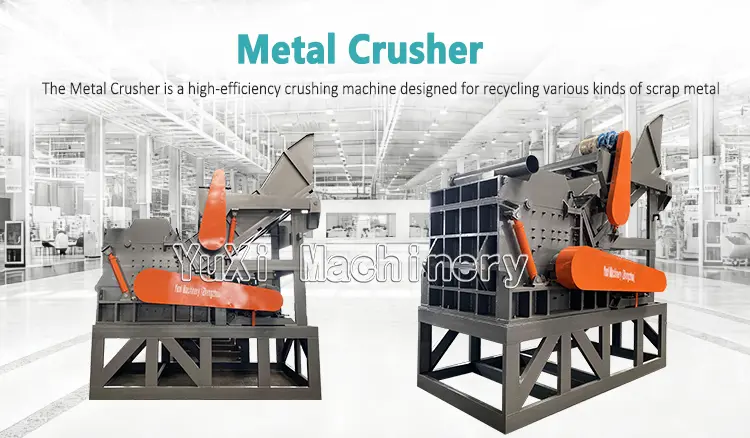

Product Overview

The Metal Crusher is a high-efficiency crushing machine designed for recycling various kinds of scrap metal. By using high-speed rotating hammers or blades, it performs impact, shear, and extrusion on the materials to achieve rapid size reduction. The crushed metal particles are uniform and easy for subsequent separation, briquetting, or smelting, making it an ideal solution for metal recycling and processing industries.

Application

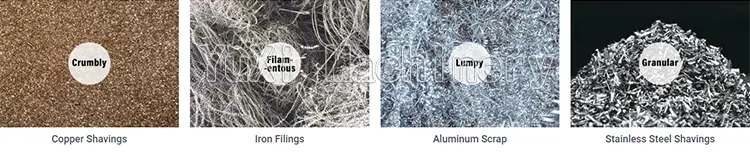

The metal crusher is suitable for processing:

- Waste car shells, bicycles, motorcycle parts

- Aluminum profiles, cans, tin cans, steel drums

- Scrap steel plates, iron bars, paint buckets, color steel tiles

- Copper, aluminum, motor shells, and metallic parts from circuit boards

- It is widely used in scrap metal recycling plants, renewable resource centers, and steel mills.

Working Principle

- Feeding: Scrap metal is conveyed into the crushing chamber;

- Crushing: The rotating hammers or blades impact, tear, and squeeze the material until it reaches the required size;

- Screening: A built-in screen classifies the crushed materials, returning oversized pieces for further crushing;

- Discharging: Qualified metal granules are discharged and can be separated by magnetic or eddy current separators.

- The system can be equipped with magnetic separators, eddy current separators, and dust collectors for fully automated and eco-friendly operation.

Advantages & Features

- High Efficiency: Powerful motor and optimized hammer design ensure high throughput and uniform output.

- Automation: PLC control system enables intelligent operation and fault monitoring.

- Easy Maintenance: Modular structure allows quick disassembly and maintenance.

- Strong Adaptability: Handles various shapes and thicknesses of metal materials.

- Energy Saving & Eco-Friendly: Enclosed crushing chamber with dust removal system minimizes noise and pollution.

- Safe & Reliable: Heavy-duty design and safety protections ensure stable and secure operation.