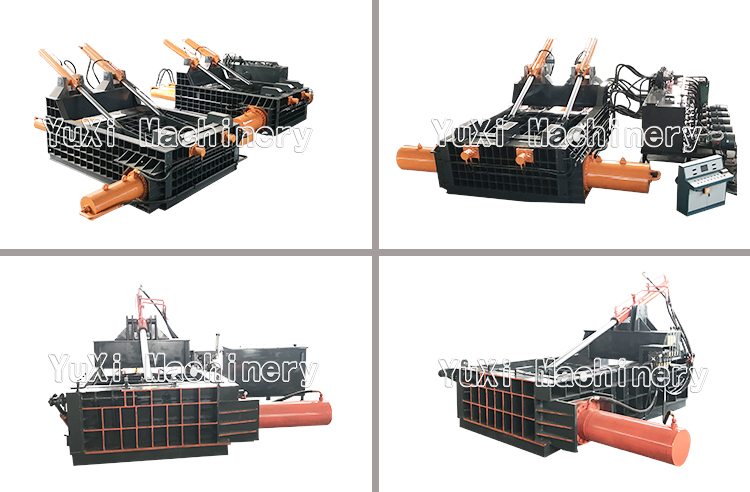

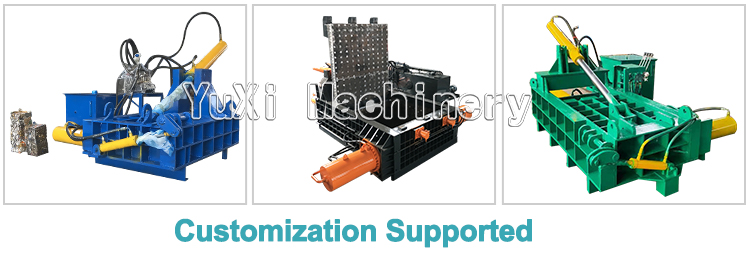

What is a Scrap Metal Baler?

The scrap metal baler is a horizontal compression device designed specifically for scrap metal recycling. It uses a hydraulic drive system to strongly compress loose scrap metal and pack it into regular blocks with high density and small volume, which is convenient for subsequent transportation, storage and processing, and solves the problem of scrap metal taking up large space and high transportation costs.

What materials can be processed?

Thin metals: such as scrap iron, aluminum, foil, and cans;

Metal scraps: including metal scraps, metal shavings, scrap wire, wire mesh, etc.;

Small metal parts: such as discarded small hardware, old metal parts, and metal bottle caps;

Other loose metals: such as dismantled scrap metal fragments and metal packaging.

Working Principle

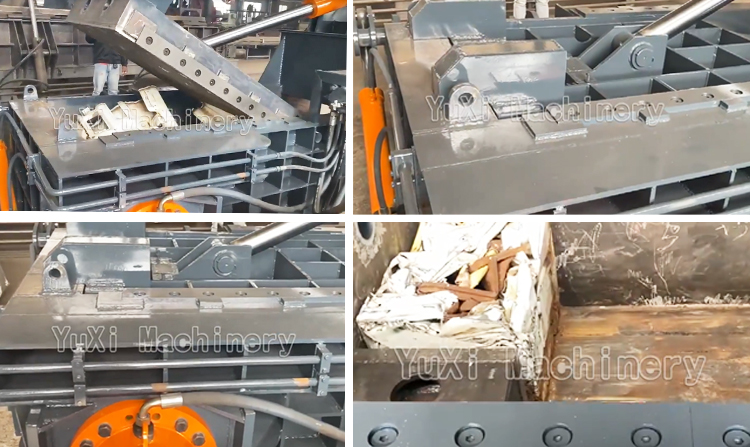

Raw material feeding: Loose scrap metal is evenly placed into the equipment’s feed hopper.

Hydraulic drive: After the equipment is started, the hydraulic system pushes the ram into the hopper.

Powerful compression: The ram applies high pressure to the metal raw material, squeezing it into compacted blocks.

Bagging: After compression, the ram is secured by a strapping device and then ejected, completing the baling process.

Advantages and Features

Efficient Compression: The hydraulic system provides powerful pressure, high compression density, and compacted bales, reducing transportation and storage costs.

Automated Operation: One-touch start automates the feeding, compression, and bundling processes, reducing labor.

Durable and Stable: The machine body is constructed of thickened steel and high-quality hydraulic components, ensuring long service life and stable operation.

Safe and Reliable: Equipped with safety devices such as overload protection and emergency stop to prevent equipment failure and personnel risks.