Product Overview

The Waste Rotor Recycling Machine is specially designed for dismantling and recycling copper, aluminum, and iron from waste motor rotors and stators. It integrates crushing, magnetic separation, and air separation technologies to achieve efficient recovery of valuable metals without pollution.

This system is widely used in motor recycling plants, e-waste recycling, and renewable resource industries, providing high recovery rates and reduced manual labor costs.

Application Scope

- Waste motor rotors and stators

- AC and DC motors

- Household appliance motors (fan motors, compressors, drills, etc.)

- Industrial and automotive motors

- Mixed copper-aluminum rotor components

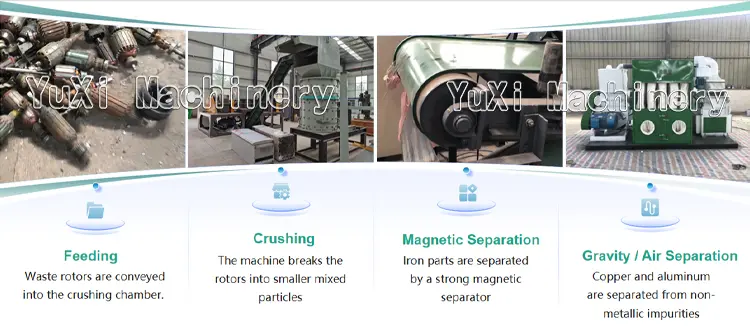

Working Process

- Feeding: Waste rotors are conveyed into the crushing chamber.

- Crushing: The machine breaks the rotors into smaller mixed particles.

- Magnetic Separation:Iron parts are separated by a strong magnetic separator.

- Gravity / Air Separation:Copper and aluminum are separated from non-metallic impurities using airflow or vibration separation.

- Metal Collection:High-purity copper, aluminum, and iron are collected for smelting or reuse.

Advantages & Features

- High Separation Purity:Up to 99% recovery rate for copper, aluminum, and iron.

- Fully Automatic System:Controlled by PLC for stable and safe operation.

- Eco-friendly Process:Dry-type separation, no chemical pollution or wastewater.

- Compact & Modular Design:Easy installation and flexible layout.

- Low Noise & Energy Consumption:Optimized transmission and insulation systems.

- Durable & Easy Maintenance:Made with wear-resistant components for long service life.