What Is a Radiator Recycling Machine

As a professional metal recycling equipment supplier, our radiator crushing and sorting system is specifically designed for the recycling of used automotive and industrial radiators. Through intelligent crushing and precise sorting technology, it efficiently separates and purifies aluminum, copper, iron, and other metals, helping you build an environmentally friendly and high-yield metal recycling line. The system is compatible with various radiators (such as automotive radiators, air conditioner radiators, and industrial heat sinks), and fully automates the entire process from crushing to sorting, significantly reducing labor costs and increasing resource recovery efficiency.

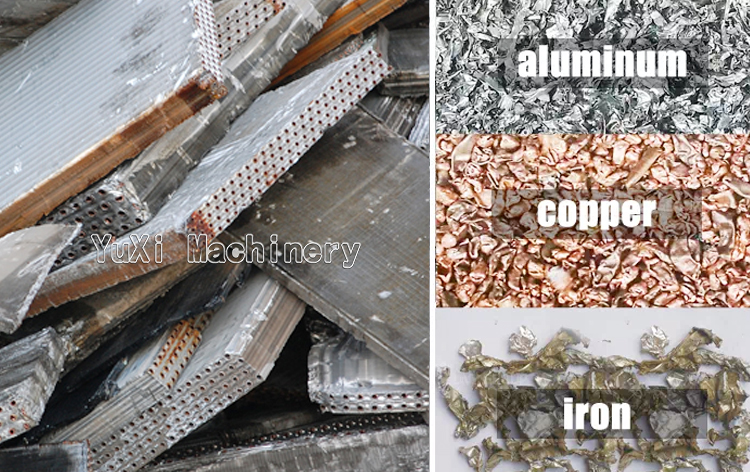

Recyclable Materials from Radiators

Copper Tubes: Used in electronics, plumbing, and wire manufacturing.

Aluminum Fins: Recycled into automotive parts, packaging, and construction materials.

Iron/Steel Housings: Can be separated and sold as scrap metal.

Who Should Use Radiator Recycling Machines

Auto dismantling plants: Recycling aluminum and copper from used car radiators and condensers.

Home appliance recycling companies: Processing metal separation from air conditioner and refrigerator radiators.

Industrial waste processing: Recycling discarded cooling components from machinery manufacturing.

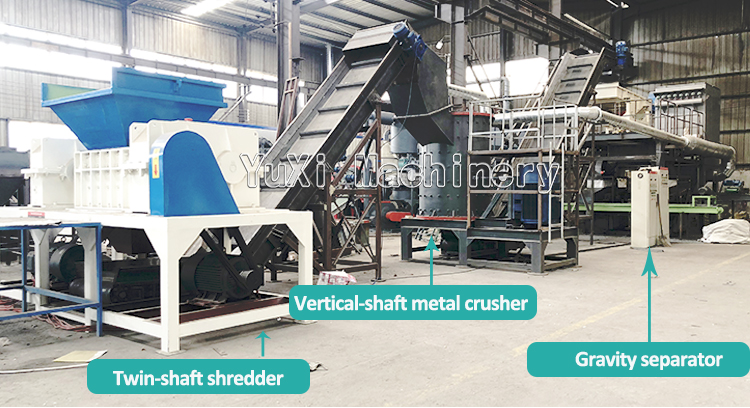

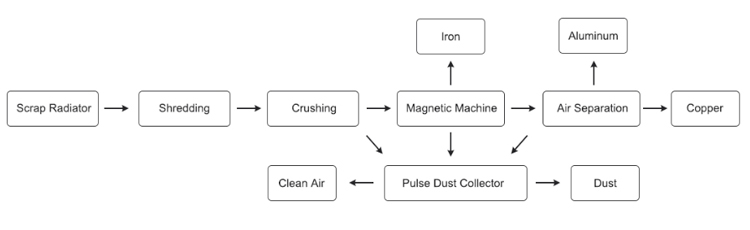

How Does Radiator Recycling Machine Work

1.Twin-shaft shredder: Shreds the entire radiator assembly into 5-10cm chunks, breaking solder joints and preparing for subsequent shredding.

2.Vertical-shaft metal crusher: Further crushes the shredded material into 1-3cm particles, completely separating aluminum foil, copper tubes, and iron sheets.

3.Magnetic separator: Uses strong magnetic rollers to separate ferromagnetic materials.

4.Gravity separator: Utilizes the density difference between aluminum and copper to separate the two non-ferrous metals through air and vibration screening.

5.Dust removal system: Collects dust and debris generated during the shredding and sorting process for discharge in compliance with standards.

Benefits of Using a Radiator Recycling Machine

1.The dual-shaft shredder features a low-speed, high-torque design for handling metal and non-metal composites, reducing tool wear.

2.The vertical-shaft metal crusher, with its three-dimensional crushing chamber and multi-angled cutters, ensures uniform metal particle size and avoids separation problems caused by over-crushing.

3.The magnetic separator, with its adjustable magnetic strength, accommodates materials with varying iron content, achieving separation efficiencies exceeding 99%.

4.The gravity separator, with its intelligent air volume control system, precisely adjusts parameters based on different material characteristics, achieving purity levels exceeding 95%.

5.The dust removal system, featuring pulsed dust removal technology, efficiently purifies the air, meeting environmental standards and safeguarding the workshop environment.