What is Radiator Recycling Plant ?

Yuxi Waste Radiator Recycling Plant is specially designed for processing waste radiators from air conditioners, vehicles, and industrial cooling systems. The system adopts a combination of shredding, crushing, magnetic separation, gravity separation, and dust removal to efficiently recover copper, aluminum, and iron. With advanced automation and high separation accuracy, it provides an environmentally friendly and profitable metal recycling solution.

Radiator Recycling Plant Video

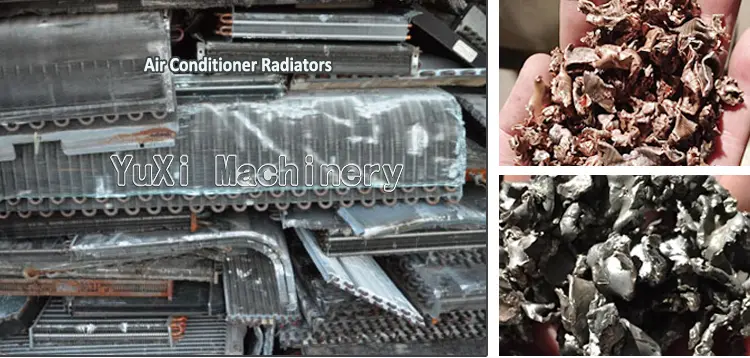

Application

- Air conditioner radiators (AC radiators)

- Automobile radiators

- Copper–aluminum water tanks

- Industrial heat exchangers and condenser units

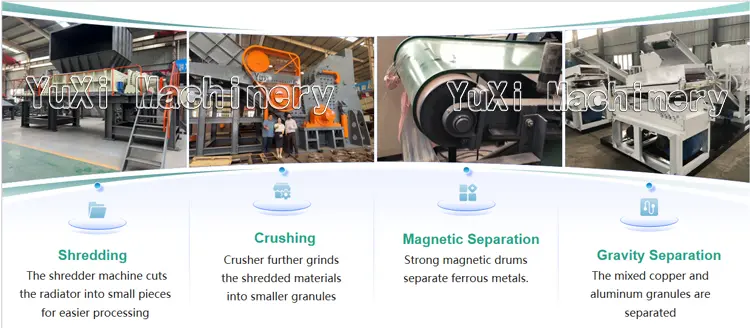

Working Process

- Feeding: Waste radiators are fed into the shredder via conveyor.

- Shredding: The shredder machine cuts the radiator into small pieces for easier processing.

- Crushing: The crusher further grinds the shredded materials into smaller granules, helping to completely separate copper, aluminum, and iron.

- Dust Removal: During shredding and crushing, a dust collection system effectively removes dust, ensuring a clean and safe working environment.

- Magnetic Separation: The magnetic separator removes iron from the non-ferrous metals.

- Gravity Separation: The mixed copper and aluminum granules are separated by a gravity separator according to density differences, achieving up to 99% purity.

- Collection: Separated copper, aluminum, and iron are collected individually for reuse or resale.

Advantages & Features

- High Metal Recovery Rate: Copper and aluminum purity up to 99%.

- Advanced Separation System: Multi-stage process ensures clean and efficient separation.

- Integrated Dust Removal: Equipped with a dust collection unit for an eco-friendly workspace.

- Automatic PLC Control: Easy operation, stable performance, and low maintenance.

- Durable Structure: Made with wear-resistant materials for long service life.

- Wide Application: Capable of handling various radiator types and sizes.