Product Overview

The Pyrolysis Steel Wire Recycling Line is a specialized system designed to separate and recover steel wire from pyrolysis residues of waste tires. It efficiently separates steel wire, carbon black, and impurities to obtain clean, high-purity recycled steel wire suitable for remelting or reuse. The system adopts a durable, wear-resistant design and PLC intelligent control to ensure continuous and stable operation, widely used in tire pyrolysis and recycling industries.

Application Scope

- Separation of steel wire and carbon black from tire pyrolysis residues.

- Metal recovery from rubber or plastic pyrolysis byproducts.

- Recycling operations in metallurgy, environmental protection, and resource regeneration.

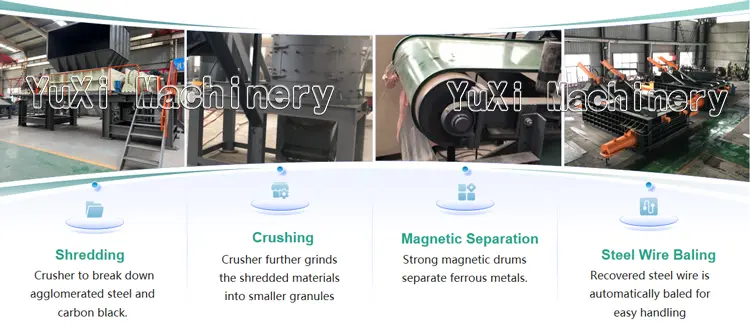

Working Process

- Feeding & Pre-Crushing

Pyrolysis residue is conveyed into a crusher to break down agglomerated steel and carbon black. - Magnetic Separation

Crushed material passes through a high-intensity magnetic separator to remove most steel wires. - Fine Separation

Remaining material undergoes secondary or tertiary magnetic and screening processes to achieve cleaner separation. - Steel Wire Cleaning & Baling

Recovered steel wire is cleaned, dedusted, and automatically baled for easy handling. - Carbon Black Recovery

Separated carbon black can be collected for reuse in making fuel, pigments, or rubber fillers.

Advantages & Features

- High Purity Separation: Multi-stage magnetic and screening processes ensure >95% steel purity.

- Smart Control System: PLC control with real-time monitoring for easy operation.

- High Efficiency & Low Energy Consumption: Optimized power usage and fast processing rate.

- Durable Structure: Core components made of wear-resistant alloy steel for long service life.

- Environmentally Friendly: Equipped with dust collection and sealing systems to minimize emissions.

- Customizable Design: Tailored configurations based on residue type and production capacity.