What is Car Shell Recycling and Separation Plant ?

The YUXI Car Shell Recycling and Separation Plant is mainly used for the comprehensive crushing and sorting of end-of-life car shells, vehicle frames, and stamped parts.

Through multiple separation technologies such as mechanical crushing, magnetic separation, eddy current separation, and air separation, the system efficiently separates iron, aluminum, copper, stainless steel, plastic, rubber, and other impurities, maximizing resource recovery and reuse.

The entire line adopts an automated PLC control system equipped with smart monitoring and anti-blocking design, ensuring stable operation, high processing capacity, low energy consumption, and easy maintenance.

Car Shell Recycling and Separation Plant Video

Application Scope

- End-of-life car shells and vehicle body frames

- Automotive stamping scraps and sheet metal leftovers

- Bicycle, e-bike, and motorcycle shells

- Various lightweight and mixed metal structures

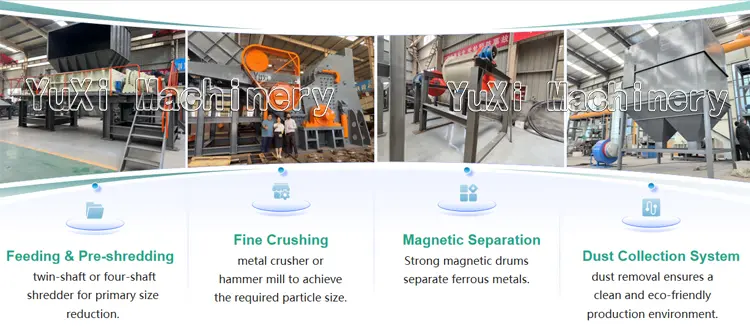

Working Process

- Feeding & Pre-shredding: Waste car shells are conveyed into a twin-shaft or four-shaft shredder for primary size reduction.

- Fine Crushing: The pre-shredded material is further processed by a metal crusher or hammer mill to achieve the required particle size.

- Magnetic Separation: Strong magnetic drums separate ferrous metals.

- Dust Collection System: Multi-stage dust removal ensures a clean and eco-friendly production environment.

- Final Product Collection: Iron, aluminum, copper, and plastic are separately collected and sent for remelting or reuse.

Advantages & Features

- High Separation Rate: Over 98% recovery rate for iron, aluminum, and copper.

- Fully Automated Control: PLC + touchscreen system enables automatic monitoring and fault alarms.

- Low Energy & High Efficiency: Optimized motor and blade design reduces energy use by 15%–25%.

- Modular Design: Easy installation, maintenance, and production expansion.

- Eco-friendly Operation: Fully enclosed conveyors and advanced dust collection minimize dust and noise.

- Strong Adaptability: Capable of processing car shells of various thicknesses and mixed metal structures.