In the recovery industry, the Airflow Specific Gravity Separator is essential for purifying materials by exploiting density differences. Whether you are cleaning recycled plastics or recovering metallic powders, your profit margins depend on the precision of this final sorting stage.

1. Precision of Airflow Control

The most important factor is the stability and adjustability of the internal air stream.

- Controlled Aerodynamics: The system must use a fan to generate a specific airflow that allows materials to float.

- Separation Accuracy: Look for a machine where you can finely adjust both the wind speed and the separation angles. This precision is what allows you to separate heavy particles from light impurities effectively.

2. Material Adaptability and Versatility

A good engineer buys a machine that can handle today’s load and tomorrow’s changes.

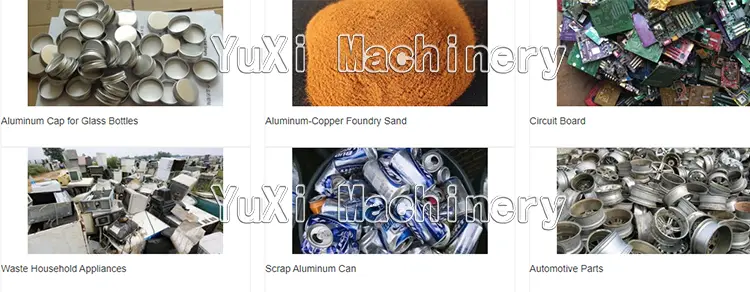

- Wide Application Range: Ensure the separator is designed to handle diverse materials, including plastic pellets, mineral particles, tire granules, and even waste paper.

- Strong Adaptability: The equipment should maintain high separation accuracy across different material types and moisture levels.

3. Automation and Continuous Production

In a modern facility, manual adjustments lead to inconsistency.

- PLC Integration: Choose a unit that is PLC-controlled. This enables continuous automated production, allowing the separator to integrate seamlessly with your upstream crushers and downstream bagging systems.

- Easy Operation: A user-friendly interface allows operators to switch between material profiles (e.g., from plastic sorting to metal powder purification) without long periods of downtime.

4. Maintenance and Structural Simplicity

Maintenance is often where “cheap” machines become expensive.

- Low Maintenance Design: Prioritize a machine with a simple internal structure. Since these separators deal with dust and light impurities, the chamber must be easy to clean to prevent cross-contamination between batches.

- Wear Resistance: Check the durability of the feeding inlet and the collection zones, as these are high-traffic areas for abrasive materials.

5. Environmental and Energy Efficiency

Operating costs are a major component of your ROI.

- Energy-Saving Features: Look for systems that optimize airflow to reduce energy consumption.

- Purely Physical Separation: Avoid systems that require chemical additives. A high-quality airflow separator should rely entirely on physics, making it an environmentally friendly choice for resource recycling.

Summary

“Choosing Yuxi means partnering with a technical leader that prioritizes high-purity material recovery and operational efficiency across its entire equipment range. From our Eddy Current Separators achieving up to 99% non-ferrous recovery to our Airflow Specific Gravity Separators that provide precise, PLC-controlled purification, we offer eco-friendly, purely physical separation solutions tailored to modern recycling needs. By combining robust, low-maintenance designs with a commitment to rapid service—including a 30-minute technical reply and a 24-hour design proposal—Yuxi ensures your recycling line delivers maximum uptime and profitability.”