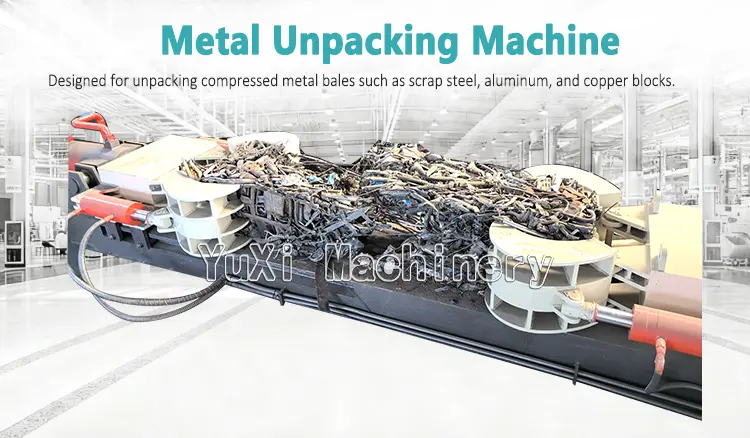

How to Choose the Right Metal Unpacking Machine: A Practical Engineering Guide

In metal recycling, a Metal Unpacking Machine is designed to break and loosen dense metal packages like scrap steel, aluminum, and copper blocks. Choosing the right one is the difference between a fluid, automated line and a bottlenecked mess.

1. Hydraulic Power vs. Bale Density

The primary job of this machine is to decompress blocks formed by high-pressure hydraulic balers.

- The “Break Force”: You must evaluate the hydraulic system’s power. If you are processing heavy scrap steel bales, you need a high-force hydraulic knife or pusher system that can penetrate the “skin” of the bale and decompose it from the inside out.

- Material Versatility: Ensure the machine can handle both ferrous and non-ferrous metal packages. A good machine should adjust its force based on whether it’s hitting soft aluminum or hardened scrap steel.

2. Structural Integrity and Impact Resistance

Unpacking metal is a violent process.

- Heavy-Duty Frame: Look for a machine with a heavy-duty steel frame. The frame must resist the constant reactive force of the hydraulic knives and the impact of heavy bales being dropped into the hopper.

- Wear-Resistant Components: Because scrap metal is abrasive, the parts that come into direct contact with the bales must be made of reinforced, wear-resistant materials.

3. Automation and System Integration

A standalone machine is rarely the goal; integration is key.

- PLC Control: Choose a machine equipped with a PLC control system. This allows the unpacking process to be synchronized with your feeding grabs or discharge conveyors.

- Continuous Flow: The right machine should enable a fully automated cycle of feeding, unpacking, and discharging. This ensures your shredder or sorting line receives a steady stream of loosened material rather than a sudden surge.

4. Customization for Bale Specifications

Bales come in all shapes and sizes.

- Adjustable Tooling: Look for a machine with customizable cutting tools and pushing systems. If your yard receives various bale sizes and densities (from car shells to appliance blocks), your unpacking machine must be adjustable to fit those specific dimensions.

- Discharge Control: Ensure the outlet is compatible with your next processing stage, whether it’s a magnetic separator or a secondary crusher.

5. Maintenance and Safety

Safety is a major engineering consideration in pre-treatment.

- Modular Design: To minimize downtime, choose a machine with a modular design. This makes replacing key parts, like hydraulic knives, much faster and more convenient.

- Environmental Protection: Enclosed operations are preferable. An enclosed machine helps contain the noise and dust generated when a dense bale is suddenly broken open.

Summary

“Choosing Yuxi for your metal recycling needs ensures a partnership built on twenty years of engineering refinement, delivering robust equipment like our Metal Unpacking Machines that seamlessly integrate into high-efficiency production lines. We combine high-force hydraulic power with intelligent PLC automation to provide reliable, customizable solutions that maximize material liberation and minimize operational downtime. Backed by international ISO certifications and a commitment to 24-hour technical support, Yuxi provides the durability and expertise required to transform challenging scrap into high-purity, profitable resources.”